Top 10 Most Common Mistakes That Cause PVC Pipe Leaks and How to Avoid Them!

When it comes to PVC plumbing projects—whether you're building irrigation systems, hydroponic setups, residential water lines or any high pressure chemical system—leaks are not only frustrating, they can also lead to major water damage, pressure loss, and costly repairs. At 247Garden, we offer top-quality Schedule 40 and Schedule 80 PVC fittings that meet or exceed ASTM D2466, D2464, D2467, F1970, UPC-PW and ANSI standards. But even the best fittings can leak if installation mistakes are made.

Here are the 10 most common reasons PVC pipes and fittings start to leak—and how to avoid them.

1. Improper Cleaning or Skipping Primer. One of the most common installation mistakes is neglecting to properly clean and prime the pipe and fitting before applying cement. Dirt, grease, or even fingerprints can interfere with bonding.

Solution:

Always use a PVC primer (such as purple primer) to clean and soften the surfaces before applying PVC solvent cement. This step ensures a chemical weld between the pipe and fitting.

2. Using the Wrong Type of Cement or Primer

Not all cements are compatible with all types of PVC fittings or applications. For example, using regular cement on a pressure system or a SCH80 joint can cause leaks under stress.

Solution:

For SCH40 or SCH80 pressure systems, use a cement that matches your application—such as heavy-duty gray cement for SCH80, or medium-body clear cement for SCH40. Confirm compatibility with pressure ratings and temperature limits.

3. Dry Fitting Before Gluing

PVC doesn't seal well without adhesive. If you're assembling a system by dry-fitting and then gluing afterward, the alignment might shift slightly, causing weak bonding and eventual leaks.

Solution:

Dry-fit only to test alignment, then immediately glue the joint while holding it firmly in place for at least 30 seconds to set.

4. Twisting After Cement Sets

Once PVC cement is applied and the parts are bonded, any twisting or repositioning will weaken the joint and can introduce micro-fractures or air gaps.

Solution:

Hold the pipe and fitting in a fixed position for 30–60 seconds after joining to ensure a full chemical weld.

5. Over-Tightening Threaded Fittings

Threaded SCH40 or SCH80 fittings like adapters and caps are easily damaged by over-torquing, which can crack the fitting and lead to slow leaks.

Solution:

Use thread sealant (not Teflon tape) made for plastic fittings and hand-tighten with only a slight additional turn using a wrench. Stop if you feel resistance.

6. Using Teflon Tape IncorrectlyTeflon tape can make it too easy to overtighten plastic threads, or may bunch up inside a joint, preventing a proper seal.

Solution:

Use a plastic-compatible thread sealant or thread paste (PTFE-free if required). Apply evenly and avoid over-wrapping.

7. Thermal Expansion or Contraction

Temperature fluctuations can cause PVC pipes to expand or contract, especially if they are installed tightly without room to move. This can stress joints and create cracks or leaks over time.

Solution:

Allow room for thermal movement, especially in long runs. Use expansion joints or flexible couplings where needed.

8. Using the Wrong Fitting for the Job

Not all PVC fittings are rated the same. DWV fittings, for example, are not designed for pressure systems. Using a DWV fitting in a pressurized line is a guaranteed leak.

Solution:

Use only pressure-rated SCH40 or SCH80 PVC fittings like those offered by 247Garden. All our fittings meet NSF and ANSI standards and conform to ASTM D2466, D2464, D2467, and F1970, making them ideal for water supply, irrigation, and structural applications.

Here are two more common mistakes that can cause PVC pipe leaks, to add to the blog:

9. Cutting the Pipe Crooked or Rough

A sloppy or uneven pipe cut leads to poor surface contact inside the fitting, which means the solvent cement won’t bond the materials evenly. This often causes small gaps that leak under pressure.

Solution:

Use a fine-toothed saw or PVC pipe cutter to make clean, square cuts. Always deburr and bevel the pipe ends with sandpaper or a deburring tool to ensure a smooth, snug fit.

10. Not Letting the Joint Cure Properly

Some users pressure test or run water through the system too soon after gluing. PVC cement needs time to cure and form a solid chemical weld—rushing this process can cause immediate or delayed leaks.

Solution:

Follow the cement manufacturer’s instructions for curing time. Typically, wait 15 minutes for handling, and at least 2 hours (up to 24 hours) before pressure testing, depending on temperature and pipe size.

Let me know if you'd like the full blog updated with these final two included.

Final Thoughts

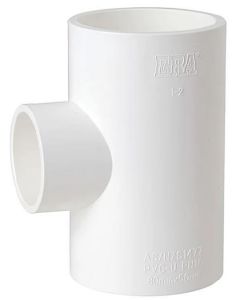

Leaks in PVC systems can be avoided by using the right materials and following best installation practices. At 247Garden, we carry a wide selection of SCH40 and SCH80 PVC pipe fittings in sizes from 1/2 inch to 6 inches, including elbows, tees, adapters, caps, couplings, and unions—all ASTM and ANSI certified for peace of mind.

If you're building or repairing a PVC system, shop with confidence at 247Garden.com and get the right fittings for the job—done once, done right.

Need help selecting the correct PVC fittings?

Contact our support team or browse our technical guides and resources to ensure a leak-free system from start to finish.