The History of Schedule 40 PVC Pipes and Fittings and Its Importance!

When Was Schedule 40 PVC Invented?

The origins of PVC (polyvinyl chloride) trace back to the late 19th century, with the earliest known discovery by German chemist Eugen Baumann in 1872. However, PVC wasn’t commercially viable until 1926, when American chemist Waldo Semon, working for the B.F. Goodrich Company in Ohio, developed a process to make PVC flexible and usable.

Rigid PVC—what we now know as Schedule 40—emerged in the 1940s and 1950s as industries searched for corrosion-resistant, affordable, and lightweight alternatives to metal piping. Formal pressure pipe standards were developed in the United States in the 1950s, and Schedule 40 PVC was officially classified under ASTM D1785 for pressure pipe, and ASTM D2466 for pressure fittings.

By the 1960s, Schedule 40 PVC was becoming a dominant force in residential, commercial, and agricultural plumbing.

Where Was It Developed?

Schedule 40 PVC pipe and fittings were developed and standardized primarily in the United States, where industrial and post-WWII infrastructure growth demanded innovative materials. Major development occurred in manufacturing hubs such as Ohio, North Carolina, and Pennsylvania, where companies like B.F. Goodrich, Charlotte Pipe, and Harvel Plastics were instrumental in commercializing PVC pressure systems.

Why Was Schedule 40 PVC Invented?

The invention of Schedule 40 PVC was driven by the need for a non-metallic pipe system that could be used for pressurized water applications. Metal pipes—such as galvanized steel and copper—were prone to corrosion, expensive to manufacture, and heavy to install. Schedule 40 PVC solved these problems by offering:

- Strong performance under moderate pressure

- Chemical and corrosion resistance

- Lightweight design for easy handling and installation

- Long service life with low maintenance

- Lower overall cost compared to traditional materials

It quickly became the material of choice for plumbing, irrigation, drainage, and venting systems.

Who Was Involved?

Several key individuals and organizations played a role:

- Waldo Semon, for his breakthrough in making flexible and usable PVC

- B.F. Goodrich, for advancing PVC chemistry and commercial use

- ASTM International, for developing the standards that define Schedule 40 pipe and fittings

- Manufacturers like Charlotte Pipe and NIBCO, for scaling up production and setting the standard for quality fittings

How Is Schedule 40 PVC Made?

Schedule 40 PVC is made by polymerizing vinyl chloride monomer into a white plastic resin. That resin is then melted and extruded into cylindrical pipe forms with controlled wall thickness. The thickness of the wall for Schedule 40 pipes corresponds to specific pressure ratings.

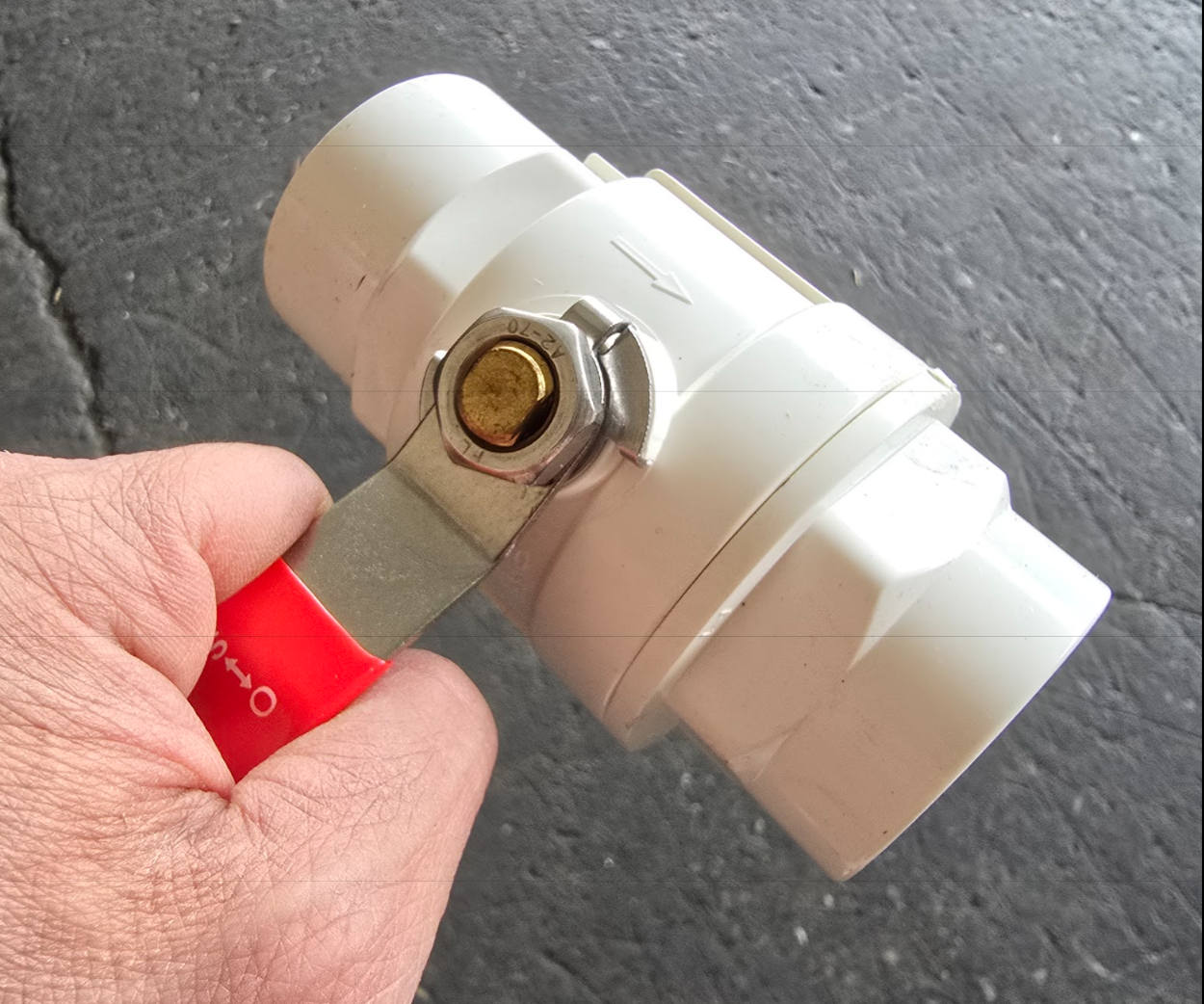

Fittings—such as elbows, tees, caps, and couplings—are either injection molded or fabricated to match the dimensions of the pipes, based on the requirements of ASTM D2466 for pressure fittings.

Schedule 40 PVC is available in sizes from 1/2 inch to over 6 inches in diameter and is rated for pressures up to 450 PSI depending on the size.

247Garden: A Modern-Day Pioneer in Schedule 40 PVC

While the mid-20th century gave the world the material innovation of Schedule 40 PVC, the 21st century demands better access, lower prices, and more flexibility—and that’s where 247Garden plays an essential role. Whether you're building a residential irrigation system, a raised-bed garden with drip lines, or a PVC structure for a greenhouse, 247Garden is here to support your business and your hobbies!

A Full Range of Products for Professionals and Hobbyists Alike

247Garden offers a comprehensive selection of Schedule 40 fittings, including:

- Slip and threaded elbows

- Tees, wyes, and crosses

- Adapters, bushings, caps, and plugs

- Reducing fittings and specialty connectors

These are available in sizes from 1/2 inch to 6 inches and bigger, all compliant with ASTM standards and designed to handle pressure systems with confidence.

Supporting a Wide Range of Industries

247Garden’s Schedule 40 fittings are trusted in:

- Home plumbing systems

- Greenhouse irrigation

- Raised bed watering projects

- Aquaponics and hydroponics setups

- Pool plumbing

- Low-pressure industrial systems

- Educational and prototyping environments

Why 247Garden Matters in the 21st Century

Schedule 40 PVC was born in the mid-20th century as a solution to rising demands for a better piping material. Its success transformed plumbing, agriculture, and construction around the world. In the modern era, innovation isn’t just about materials—it’s about access, flexibility, and service. 247Garden is committed in providing affordable pricing and supporting growers, builders, inventors, and problem-solvers with high quality fittings and parts. Today, 247Garden continues its committment by making Schedule 40 PVC more accessible, affordable, and flexible than ever before. From backyard gardens to small farms, from creative DIY builds to professional installations, 247Garden ensures that every project—big or small—can benefit from professional-grade fittings without industrial-scale barriers.

If you're looking for reliable, ASTM-certified Schedule 40 PVC fittings, backed by years of industry knowledge and customer service, 247Garden is here for you!