How a True-Union Ball Check Valve Works: A Practical and Detailed Explanation

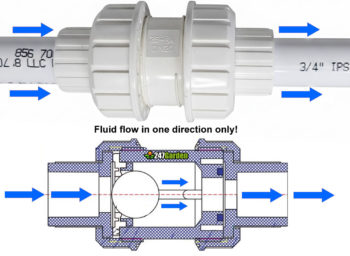

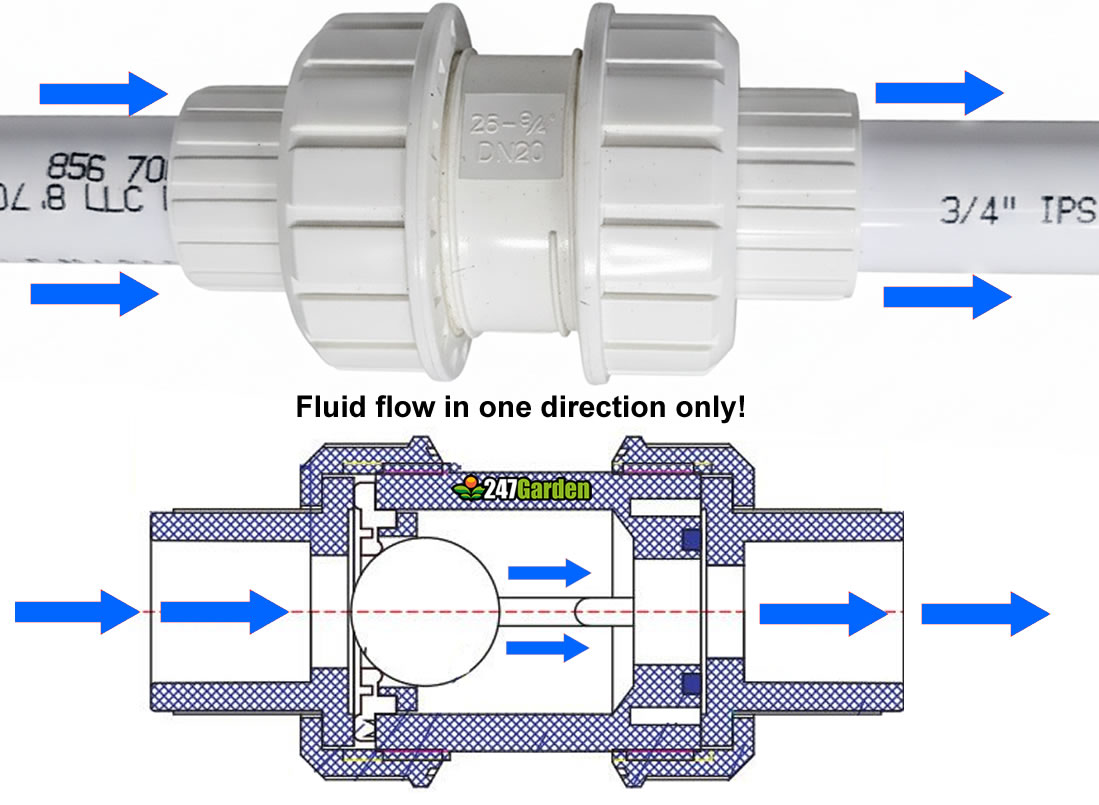

A True-Union Ball Check Valve is a non-return valve designed to allow fluid to flow in one direction only while automatically preventing backflow. It operates using a free-floating ball that seals against a seat when flow reverses.

It’s called a “true-union” valve because both ends of the body have union fittings, allowing the valve body to be removed for cleaning or maintenance without cutting or re-gluing any pipe.

How It Works — Step by Step

1. Forward Flow (Normal Operation)

When fluid enters from the inlet side, the pressure pushes the ball away from the seat, creating an open passage.

The ball moves slightly upward or downstream, depending on the valve’s orientation, allowing the liquid to pass freely through the valve with minimal resistance.

At this point, the valve is open, and flow continues normally.

2. Reverse Flow (Backflow Prevention)

When flow stops or attempts to reverse direction, pressure from the opposite side or gravity causes the ball to move back onto the seat.

The ball seals tightly against the valve seat, blocking fluid from returning through the line.

This automatic action prevents siphoning, contamination, or pressure loss in upstream equipment such as pumps or tanks.

At this point, the valve is closed, preventing backflow.

3. Automatic Reset

As soon as forward pressure resumes, the ball lifts again, reopening the passage for normal flow.

This cycle repeats automatically and requires no manual operation or external control.

Internal Components and Functions

| Component | Description |

|---|---|

| Valve Body | The main housing, typically made of PVC, CPVC, or PVDF for corrosion and chemical resistance. |

| Union Ends x 2 | Allow quick removal of the valve body for cleaning or replacement without disturbing the rest of the pipeline. |

| Ball | The moving element that seals or unseals the flow path. It is usually made from PVC or a weighted material. |

| Seat | The sealing surface against which the ball rests to block reverse flow, typically made from EPDM or Viton. |

| O-Rings | Provide leak-free seals between the union ends and valve body. |

Practical Example — Irrigation or Hydroponics

Consider a hydroponic system with a pump circulating nutrient solution to multiple grow lines:

- When the pump is running, pressure lifts the ball, allowing fluid to flow freely through the valve.

- When the pump stops, gravity and reverse pressure push the ball back against the seat, preventing the nutrient solution from draining backward into the reservoir.

This prevents siphoning, air introduction, and cross-contamination between different parts of the system.

The same principle applies to irrigation lines, chemical dosing systems, aquarium returns, and industrial water loops.

Why the “True-Union” Design Matters

Many check valves are glued or threaded permanently into a pipeline. When they fail or clog, the only way to service them is to cut out the valve and replace it.

With a true-union design, you can:

- Unscrew both union nuts,

- Remove the valve body,

- Clean or replace the internal parts,

- Reinstall it easily.

This design saves time, reduces downtime, and extends the system’s service life.

Key Advantages

- Reliable automatic backflow prevention

- Simple design with minimal moving parts

- Easy maintenance and cleaning

- Resistant to corrosion and chemicals

- Works in both horizontal and vertical installations (vertical flow-up is preferred)

- Compatible with Schedule 40 or Schedule 80 piping

Example: 247Garden True-Union Ball Check Valves

For dependable performance in industrial, agricultural, and water treatment systems:

- 1/2" to 2" sizes – Ideal for Schedule 40 PVC piping in hydroponics, irrigation, or aquarium systems.

- Up to 4" sizes – Suitable for Schedule 80 piping in higher-pressure industrial or municipal systems.

Each 247Garden True-Union Ball Check Valve features:

- Durable PVC body and union ends,

- Precision-molded sealing ball and seat,

- EPDM or Viton seals for broad chemical compatibility,

- Easy serviceability and long-term reliability.