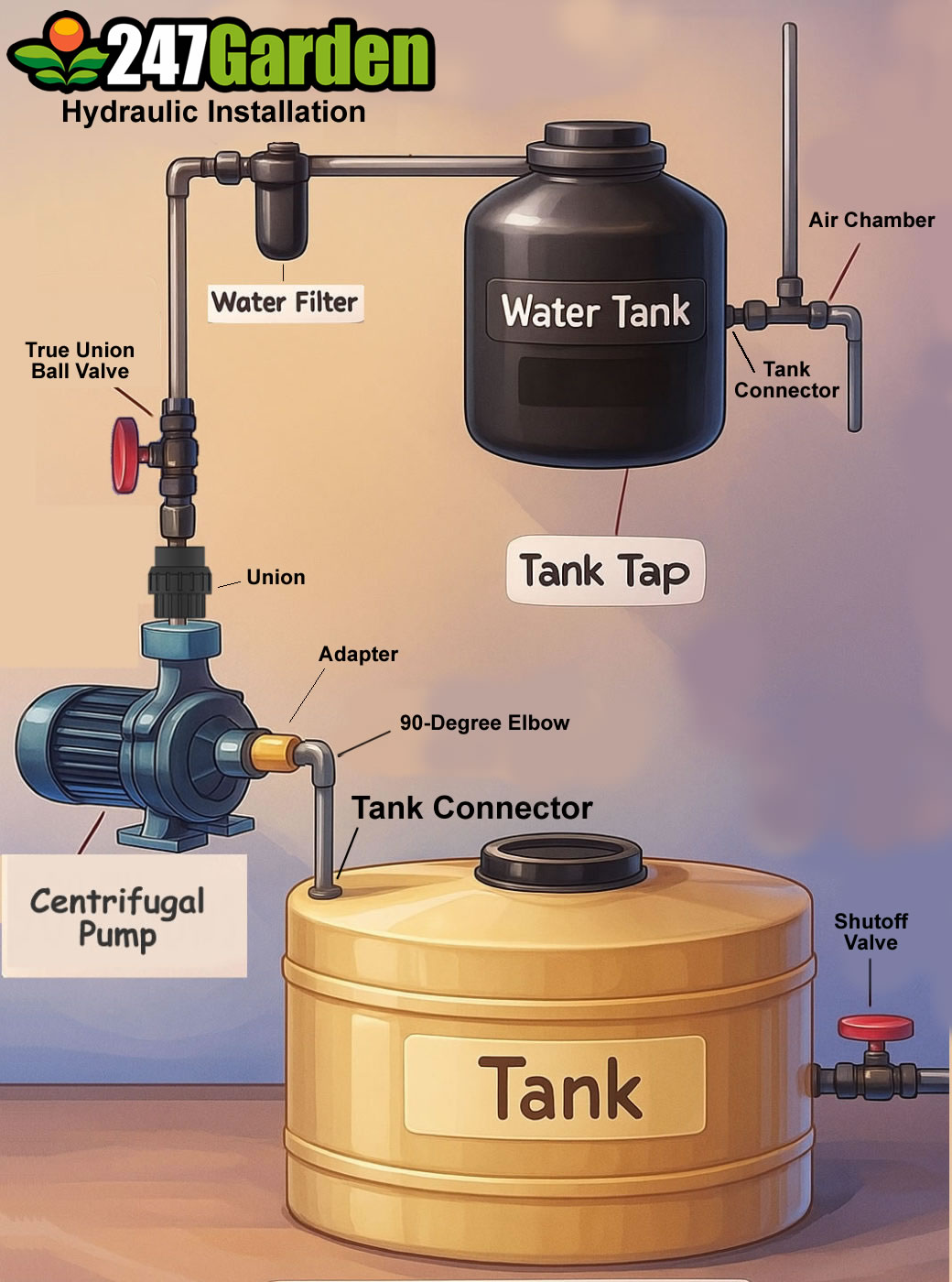

247Garden Hydraulic Installation: Connecting a Water Tank to a Reservoir

Hydraulic installations are the backbone of reliable water management systems, whether for irrigation, construction, or industrial applications. One of the most common projects is connecting a water tank to a reservoir. At 247Garden, we place a strong emphasis on material selection, system design, and proper installation techniques to ensure performance, safety, and long-term durability.

This guide focuses on installing a Water Tank to Reservoir Hydraulic System using 1 inch ASTM D2467 Schedule 80 PVC system, rated to PN16 standards.

Why Schedule 80 is Essential

When connecting a tank to a reservoir, the system is often subject to high pressure and fluctuating loads. Schedule 80 PVC is chosen for several reasons:

- Higher Pressure Rating: Thicker walls allow SCH80 to handle greater internal pressure compared to SCH40.

- Durability: Better resistance to impact, mechanical stress, and long-term wear.

- Sealing Reliability: Reduced risk of cracks or leaks when tightened to PN16 standards.

- Versatility: Suitable for both industrial and civil applications where reliability is critical.

For installations that must withstand long service life, SCH80 is the safe choice.

Step 1: Positioning the Tank and the Reservoir

Both the tank and reservoir should be placed on solid, level foundations, typically reinforced concrete, to minimize vibration and uneven loading. The elevation difference between the tank and reservoir must also be considered to take advantage of gravity-assisted flow and reduce strain on the pump.

Step 2: Installing the Centrifugal Pump

The centrifugal pump is the driving force behind water circulation in this setup. It should be installed on a stable, vibration-dampening base, positioned close to the water source. Alignment with inlet piping is crucial. When tightening flanges and bolts, always follow PN16 torque guidelines to ensure sealing integrity and prevent premature gasket wear.

Step 3: Setting Up Pipes and Fittings

Here is where ASTM D2467 Schedule 80 PVC 1 inch fittings come into play. These are engineered for high-pressure environments and offer superior mechanical strength. Commonly used fittings include:

- Elbows for changing pipe direction without excessive head loss

- Unions for disassembly and maintenance access

- Ball and Check Valves for controlling flow and preventing backflow

- Flanges with Gaskets for PN16-rated tight connections

Every fitting contributes to system efficiency, so selecting SCH80 materials ensures the network can operate safely under pressure.

Step 4: Adding the Filtration System

Clean water is essential for maintaining the longevity of the pump and preventing blockages. Installing a filtration system between the tank and reservoir removes sediment, particles, and impurities. This not only improves water quality but also extends the lifespan of mechanical components throughout the system.

Step 5: Checking for Tightness and Testing the Flow

Once all components are in place, perform a pressure test at PN16 to verify joint integrity. The system should be examined for leaks at every connection point. Next, run the centrifugal pump to confirm:

- Flow rate meets project requirements

- Pressure remains stable

- No trapped air is present in the pipeline

- All seals hold securely under operation

Testing under full working conditions ensures the installation will remain reliable in long-term use.

Engineering and System Performance

The strength of this type of hydraulic installation lies in combining civil engineering design with hydraulic precision. By selecting Schedule 80 ASTM D2467 1 inch fittings instead of lighter-duty alternatives, the installation is capable of withstanding demanding operating conditions.

The outcome is a durable, efficient, and safe water transfer system suitable for infrastructure, agriculture, or industrial applications.

Final Thoughts

At 247Garden, we provide Schedule 80 PVC fittings and components designed for high-performance hydraulic systems. Whether for irrigation, construction, or large-scale reservoir projects, investing in quality materials ensures flow rate, pressure, and sealing are consistently maintained.