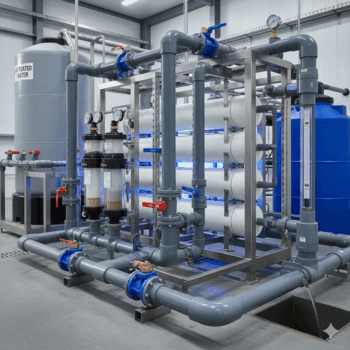

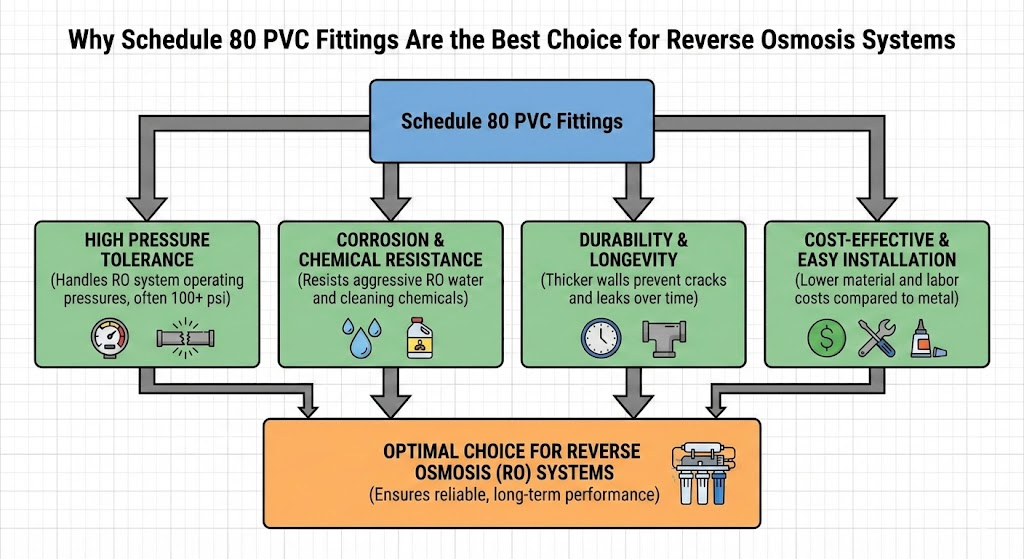

Why Schedule 80 PVC Fittings Are the Best Choice for Reverse Osmosis Systems

Schedule 80 PVC fittings play an important and reliable role in reverse osmosis (RO) systems, especially in commercial, agricultural, and industrial setups. Here’s how they fit in and why they’re commonly chosen:

1. Handles High Pressure in RO systems

Reverse osmosis systems operate under significant pressure to force water across a semipermeable membrane.

- Typical RO operating pressure ranges: 80–250 PSI (sometimes higher in commercial units).

- Schedule 80 PVC fittings have a much higher pressure rating than Schedule 40, making them ideal for the feed lines, manifold piping, and high-pressure sections of the system.

This ensures the plumbing won’t crack, leak, or deform under continuous pressure.

2. Corrosion Resistance — No Rust, No Metal Contamination

RO systems demand pure, clean water, and metal piping can leach contaminants.

- Schedule 80 PVC is non-metallic and 100% corrosion-resistant.

- It won’t react with salts, chloramines, or chemicals used in pre-treatment (like carbon filters or anti-scalants).

This is critical because any contamination risks damaging the RO membrane.

3. Chemical Compatibility

RO setups often include:

- carbon filters

- softeners

- anti-scalant dosing

- chlorine-removal stages

Schedule 80 PVC fittings are highly chemical-resistant, and compatible with most fluids used in water treatment systems.

4. Long Service Life in Continuous Water Flow

RO systems run for long periods, especially in agricultural or industrial water purification.

Schedule 80 PVC fittings offer:

- long-term durability

- resistance to fatigue

- minimal maintenance

This is why they’re widely used in the food industry, hydroponics, aquaculture, and greenhouses.

5. Temperature Stability

RO systems often operate with feed water between 40°F–100°F.

Schedule 80 PVC remains structurally stable within this range and handles temperature fluctuations better than Schedule 40.

6. Common Places Schedule 80 PVC Fittings Are Used in RO

You’ll typically find these fittings in:

- Feed water supply lines

- High-pressure pump outlet manifold

- Pre-filter housings connections

- Concentrate (waste) line

- Permeate (clean water) distribution manifold

- Brine recirculation loops

- Chemical dosing injection points

Anywhere high pressure or reliability is needed, Schedule 80 is preferred.

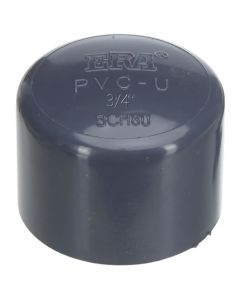

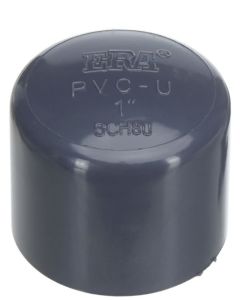

7. Why Many Installers Prefer SCH80 Over SCH40 for RO

| Feature | SCH40 | SCH80 |

|---|---|---|

| Pressure rating | Medium | High |

| Wall thickness | Standard | Thicker, stronger |

| Durability | Good | Excellent |

| Color | White | Gray (blocks algae growth) |

The gray color of SCH80 is also helpful in RO rooms where preventing light penetration reduces microbial/algae growth inside the lines.

8. Why 247Garden Schedule 80 Fittings Work Well for RO

If you’re sourcing Schedule 80 fittings for RO systems, 247Garden’s SCH80 line is ideal because:

- NSF-certified

- ASTM D2467 compliant

- High-pressure rated

- Chemically resistant

- Available in a wide range of sizes (1/2" to 4"+)

- Free mainland USA shipping

They’re especially useful for commercial RO plants, agriculture filtration rooms, and greenhouse water treatment setups.