The History and Invention of Schedule 80 PVC Pipes and Fittings and its Modern Usefulness

Why Was Schedule 80 PVC Invented?

The need for Schedule 80 PVC (Polyvinyl Chloride) arose from growing industrial demands for a non-metallic piping solution that could handle higher pressure and temperature than standard Schedule 40 PVC. While Schedule 40 pipes work well for low-pressure residential plumbing and irrigation, industries like chemical processing, manufacturing, and commercial water treatment needed something stronger and more durable—but still corrosion-resistant, lightweight, and affordable compared to metal alternatives.

When Was Schedule 80 PVC Developed?

PVC as a material was first polymerized in the 19th century (1872 by German chemist Eugen Baumann), but it wasn't until the 1930s that Waldo Semon and B.F. Goodrich created a practical plasticized version of PVC. However, Schedule-rated PVC piping—including Schedule 40 and Schedule 80—was not standardized until much later.

The ASTM D1785 standard, which governs Schedule 40 and 80 PVC pressure pipes, was published by ASTM International in the 1950s. Schedule 80 PVC likely came into regular use by the 1960s, as industrial demand for high-pressure, chemically resistant piping increased. The thicker wall of Schedule 80 PVC allows it to withstand higher pressures compared to Schedule 40 of the same diameter.

Where Was It Developed?

PVC manufacturing and piping innovation were happening in North America and Europe in parallel, but the development of Schedule-rated PVC pipes was most notably standardized and scaled in the United States, particularly in Ohio, Texas, and New Jersey—key hubs for polymer science, chemical engineering, and industrial plumbing technologies in the post-WWII era.

Who Was Involved?

Key players in the early days of PVC development and piping standardization include:

- B.F. Goodrich Company (United States) – where Waldo Semon invented a flexible form of PVC.

- ASTM International – for creating the classification standards like ASTM D1785 and ASTM D2467, which define pressure-rated pipes and fittings (including Schedule 80).

- Early PVC manufacturers like Charlotte Pipe and NIBCO who developed the infrastructure for mass production and industrial adoption.

How Was Schedule 80 PVC Made?

The process starts with polymerizing vinyl chloride monomer (VCM) into PVC resin. The resin is then extruded into pipe form with controlled wall thickness based on pressure rating standards (e.g., Schedule 40 or 80).

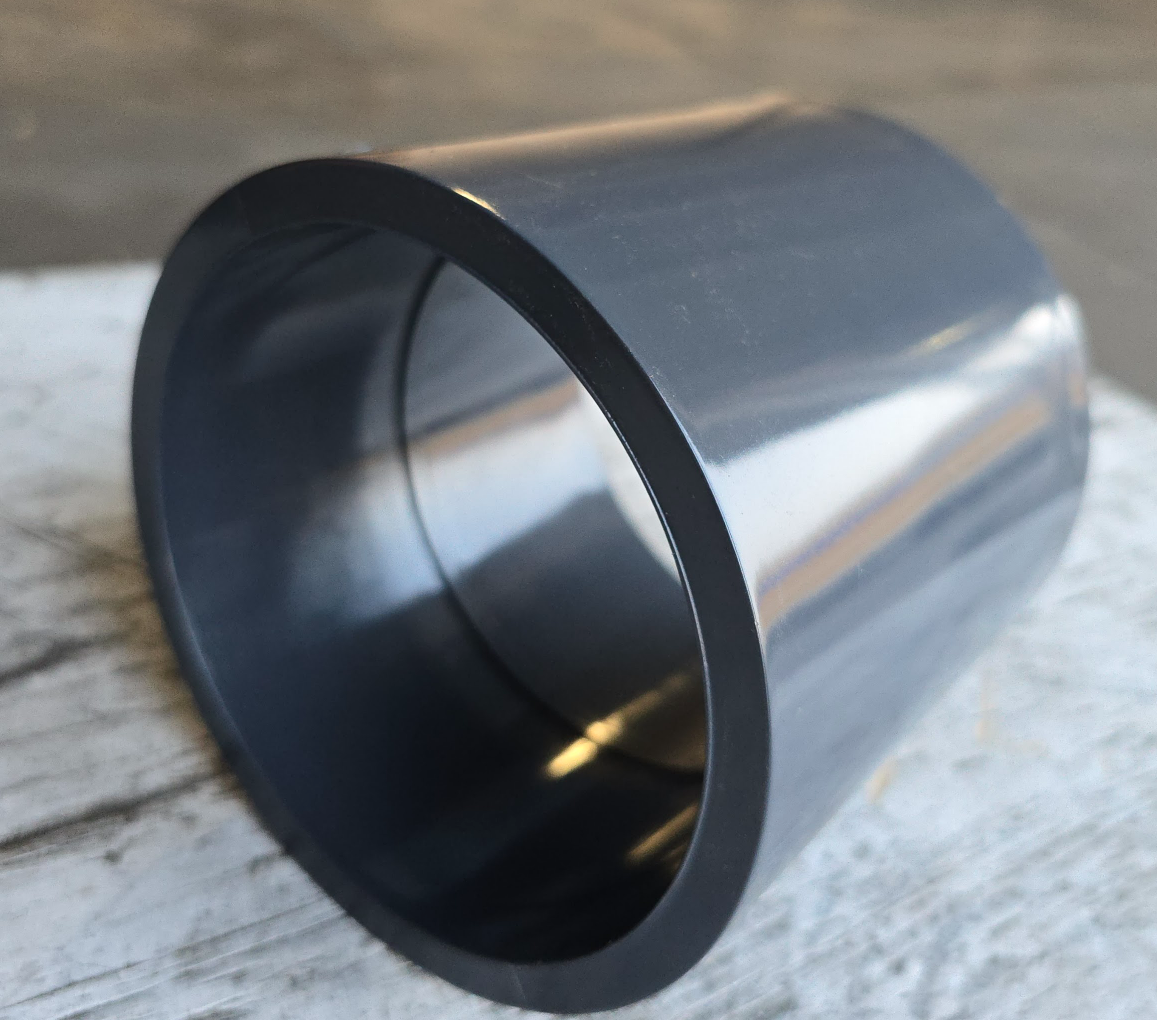

For Schedule 80, the key difference lies in its thicker walls, offering greater burst strength and chemical resistance. Fittings like elbows, tees, couplings, bushings, and valves are injection molded or fabricated using the same resin to match the pipe specifications, typically according to ASTM D2467 for pressure fittings.

Where 247Garden Fits in the Timeline

As PVC technology matured over the decades, manufacturers expanded beyond industrial markets to serve DIYers, farmers, greenhouse growers, aquaponic builders, and residential systems.

247Garden, founded in the 21st century, brings high-quality Schedule 80 PVC fittings directly to everyday users—making it easier for small farms, gardeners, engineers, and hobbyists to access high-pressure rated components without needing to go through complicated industrial suppliers.

247Garden delivers premium-grade SCH80 PVC fittings that meet or exceed ASTM D2467 standards for pressure fittings.

All Schedule 80 products from 247Garden are:

- Made from high-impact, corrosion-resistant PVC

- Built for high-pressure applications

- Offered in popular sizes from 1/2” to 6” and beyond!

- Compatible with SCH80 systems in commercial and industrial settings

- Cost-effective even in small quantities

From solar-powered pumps to custom-built vacuum chambers, the reliability and versatility of 247Garden’s SCH80 PVC fittings help people innovate, build, and grow in ways that used to be cost-prohibitive.