Introduction:

In the world of plumbing and construction, standards are paramount to ensuring the safety, reliability, and compatibility of materials and components. One such crucial standard is ASTM D2665, which specifically addresses Polyvinyl Chloride (PVC) Drain, Waste, and Vent (DWV) pipe and fittings. In this blog, we'll delve into the details of ASTM D2665, understanding its significance, specifications, and the role it plays in the plumbing industry.

Background:

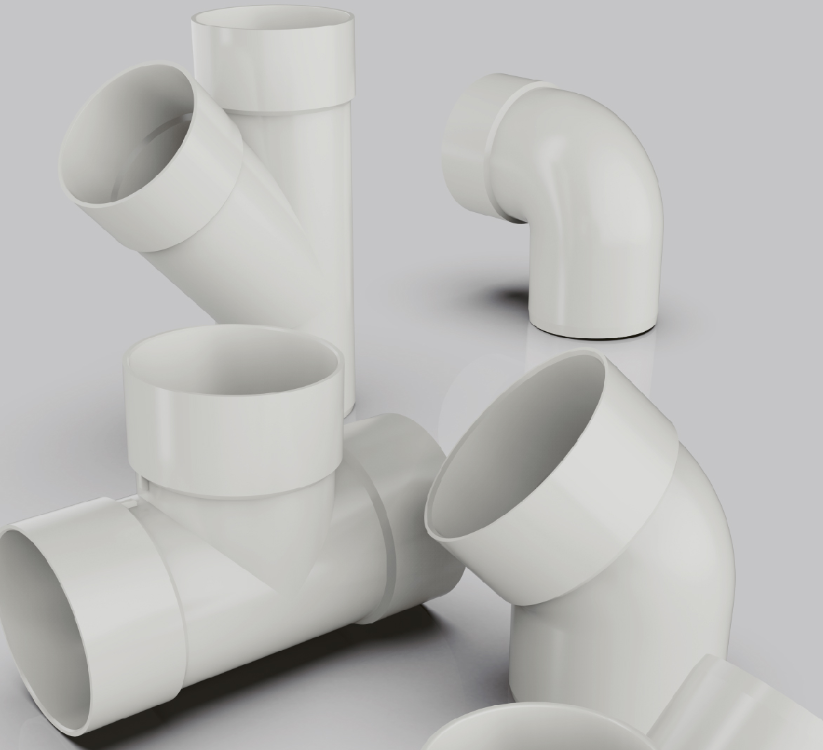

ASTM D2665 is a standard set by ASTM International, formerly known as the American Society for Testing and Materials. This organization develops and publishes technical standards for a wide range of materials, products, systems, and services. ASTM D2665 specifically focuses on PVC pipes and fittings used in DWV systems, which are essential for the safe and effective conveyance of wastewater and ventilation in buildings.

Scope of ASTM D2665:

The standard outlines the requirements for PVC DWV pipes and fittings, specifying the materials, dimensions, performance characteristics, and testing methods to ensure compliance and uniformity within the industry. Here are key aspects covered by ASTM D2665:

- Material Requirements:

- Specifies the types of PVC materials suitable for DWV pipes and fittings.

- Addresses factors such as tensile strength, impact resistance, and chemical composition.

- Dimensions and Tolerances:

- Defines the standard dimensions and tolerances for PVC DWV pipes and fittings.

- Covers a range of sizes to accommodate various plumbing system requirements.

- Workmanship, Finish, and Appearance:

- Establishes criteria for the visual and physical aspects of PVC DWV products.

- Ensures a consistent level of quality in terms of surface finish and overall appearance.

- Performance Requirements:

- Sets performance standards for PVC DWV pipes and fittings under specified conditions.

- Includes criteria for structural integrity, water tightness, and resistance to various environmental factors.

Testing Methods:

ASTM D2665 provides detailed testing procedures to evaluate the compliance of PVC DWV pipes and fittings with the specified requirements. Common testing methods include:

- Hydrostatic Pressure Testing:

- Evaluates the structural integrity of the pipes and fittings under internal pressure.

- Impact Resistance Testing:

- Assesses the ability of the materials to withstand impact forces without failure.

- Tensile Strength Testing:

- Measures the maximum stress a material can withstand while being stretched or pulled.

- Dimensional Measurements:

- Verifies that the pipes and fittings meet the specified size and tolerances.

Significance in the Plumbing Industry:

ASTM D2665 plays a critical role in standardizing the manufacturing, testing, and use of PVC DWV pipes and fittings. Compliance with this standard ensures that products from different manufacturers are interchangeable and compatible. Additionally, it provides confidence to plumbing professionals, architects, and building code officials that the materials used in DWV systems meet established quality and safety standards.

Conclusion:

In the dynamic world of construction and plumbing, standards like ASTM D2665 are the pillars that support the reliability and safety of infrastructure. The meticulous specifications outlined in this standard ensure that PVC DWV pipes and fittings adhere to a set of rigorous criteria, contributing to the longevity and efficiency of drainage, waste, and vent systems in buildings. As the industry evolves, adherence to such standards remains essential for fostering consistency, interoperability, and trust in the materials and products that shape our built environment.